1. The box, made of wood and acrylic, houses all the other parts. It acts as a support for the whole machine, and also functions as the part that connects the whole machine together.

2. The base, which is made of aluminum with a layer of rubber padding at the bottom, is designed to provide support on the table and ensure that the machine does not move laterally during operation. It also acts as a mounting platform for the guide rails and the motor holder.

3. The motor axle, made of a single aluminum rod, is used to hold the rotating arms in place and also acts as the axle on which the arm rotates about.

4. The motor holder. It is made of sheet steel on the sides and acrylic on the bottom. It is designed to hold a motor which drives a rack and pinion on the arm so that the arm can be extended and contracted at will.

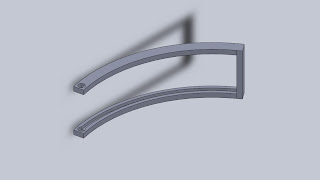

5. The guide rails. These 2 rails serve to guide the motion of the motor holder as the arm sweeps up, restraining its degree of freedom and also providing support to the motor holder.

When assembled, the MCM looks like this:

When assembled, the MCM looks like this:

The fully assembled machine looks like this:

Here, you can see how the arm is made to rotate about the motor axle, and how the motor holder is interfacing with the arm. The guide rails are also supported through a cut on the top of the box so that they will not break under the weight of the motor holder and motor combined.

Here, you can see how the arm is made to rotate about the motor axle, and how the motor holder is interfacing with the arm. The guide rails are also supported through a cut on the top of the box so that they will not break under the weight of the motor holder and motor combined.The detailed list of materials can be found here: http://bit.ly/36YHQn

The step-by-step manufacturing plan can be found here: http://bit.ly/1YgNyU

No comments:

Post a Comment